PCB Assembly

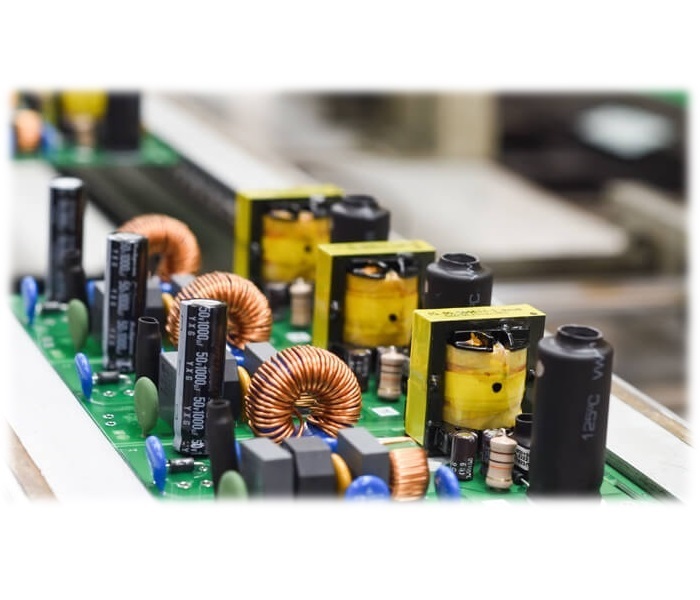

PCB Assembly, a critical and complex phase in Electronics Product Design, plays a pivotal role in ensuring the performance and safety of mobile chargers and adaptors. As the demand for electronic devices like mobile chargers and adaptors continues to grow exponentially, factors such as user expectations, heightened functionality demands, and the pursuit of smaller device footprints are driving significant advancements in PCB Assembly techniques.

At MTI Connectech, we specialize in PCB Assembly for mobile chargers and adaptors, offering comprehensive solutions that encompass Through Hole (THT), Surface Mount Technology (SMT), or a hybrid approach. Our EMS team is dedicated to tailoring these precise assembly techniques to meet the unique requirements of our clients in the mobile charger and adaptor industry. We understand the critical importance of PCB Assembly in delivering high-quality, reliable products to our valued customers in this niche market segment.

MTI Connectech proudly presents a state-of-the-art, fully automated laser marking machine specially designed for the precise marking of 1D, 2D, QR Codes, text, symbols, and graphics on mobile charger and adaptor surfaces. Our commitment to excellence in mobile charger and adaptor production extends to our cutting-edge laser marking equipment, ensuring the highest quality standards for our products. Equipped with a high-performance SYNRAD laser head crafted in the USA, this machine features an XY high-precision motion platform, guaranteeing an impressive repeatable positioning accuracy of ±0.025mm. Additionally, it boasts a CCD visual system for enhanced precision, an adjustable conveyor with automatic width adaptation, and an integrated camera for online barcode reading. At MTI Connectech, we are dedicated to delivering top-notch solutions to meet the unique needs of our clients in the mobile charger and adaptor industry.

MTI Connectech proudly introduces an exceptional high-performance 1.2m Semi Printer tailored to meet the specific needs of the mobile charger and adaptor industry. Renowned for its precision and outstanding features, this advanced printer incorporates built-in ±8-micron alignment and ±15-micron wet print repeatability, ensuring superior accuracy (≧2.0 Cpk@6sigma). It boasts an impressive total throughput of just 7 seconds, encompassing both print and stencil cleaning cycles. Our versatile printer is designed to accommodate PCB boards used in mobile charger and adaptor production, range from 1200mm TO 1500mm. It offers a swift 2-minute product changeover time and a rapid 5-minute new product setup process, enhancing efficiency and productivity in our commitment to delivering top-notch solutions for our valued clients in the mobile charger and adaptor industry.

We have 2 FZ-125-507 RAM TYPE INJECTION MOULDING MACHINES with a capacity of 125 tons each. These machines are used to manufacture high-quality cabinets and Use for mobile chargers. Machine injection rate is 132cc per second, which enhances our production efficiency. We proudly operate under the name MTI Connectech, and our work is always based on high standards and precision.

MTI Connectech employs a customized motorized conveyor solution to efficiently manage the manual placement of various components onto bare PCBs, a crucial process in the production of mobile chargers and adaptors. Following manual insertion, these PCBs seamlessly progress into the wave soldering phase, followed by meticulous touch-ups and a rigorous regimen of quality inspections and testing. Our dedicated process and quality teams leave no stone unturned in ensuring the delivery of nothing short of excellence, all in strict adherence to client requirements. At MTI Connectech, we are committed to exceeding expectations, providing top-tier solutions that consistently align with our clients' exacting standards and expectations in the mobile charger and adaptor industry. Your satisfaction is our ultimate priority, and we stand ready to meet your unique needs in every project, ensuring the highest quality and reliability in every mobile charger and adaptor we produce.

MTI Connectech takes pride in our advanced Dual Wave (SMT) Soldering- 300D (Finger Type Automatic), which plays a pivotal role in ensuring the high-quality production of mobile chargers and adaptors. Our state-of-the-art machine is equipped with a precision-driven closed-loop inverter control system, guaranteeing unwavering stability and accuracy in conveyor speed. We employ hot air heating technology in the preheating zones for optimal performance tailored to mobile charger and adaptor production. To ensure uniform flux coating, our machine utilizes a cutting-edge spray flux system, powered by a highly precise stepping motor. Its modular design seamlessly accommodates the soldering needs of both SMT and THT component types, aligning with the diverse requirements of our clients in the mobile charger and adaptor industry. Furthermore, our machine incorporates a centrifugal exhaust fan with double filters to prevent any flux residue from affecting PCBs in real-time production. The built-in forced air cooling system ensures the attainment of the desired cooling down slope, maintaining quality and precision throughout the soldering process. At MTI Connectech, we are committed to delivering cutting-edge solutions that meet and exceed industry standards for mobile charger and adaptor manufacturing, ensuring the highest quality and reliability in every product we produce.

Introducing the MTI Connectech-customized Yamaha YV100X, a high-speed, high-volume SMT (Surface Mount Technology) solution tailored to the specific needs of mobile charger and adaptor manufacturing. This adaptable solution is designed to excel in the production of mobile chargers and adaptors, offering exceptional precision and performance. Our customized Yamaha YV100X features a space-efficient dual-beam design, a robust frame, an advanced head, and the renowned Multi Recognition Camera technology for precise component placement accuracy down to 30 micrometers. Under the guidance of MTI Connectech, this system unleashes its full potential, enabling an impressive maximum Cycles Per Hour (CPH) of 24,000 on your SMT line, revolutionizing your mobile charger and adaptor production capabilities with unmatched precision. Elevate your manufacturing processes in the mobile charger and adaptor industry with the MTI Connectech-customized Yamaha YV100X, effortlessly meeting your production targets and delivering top-tier solutions tailored to your specific requirements.

MTI Connectech proudly presents KS-635 6 Zone SMT Reflow Ovens, a cutting-edge solution meticulously tailored to meet the precise soldering needs of the mobile charger and adaptor industry. Our reflow ovens are fully equipped for Industry 4.0 readiness, ensuring stable and repeatable soldering profiles that uphold the highest quality standards. Featuring independent air velocity control and a temperature-controlling system, our solution offers unparalleled flexibility to accommodate the complex soldering requirements of mobile charger and adaptor production with ease. The inclusion of extended heating zones enhances production efficiency and throughput significantly, meeting the demands of our clients in this dynamic industry. Our advanced flux management and cooling system, complete with dual independent heat exchangers, guarantee maximum cooling effectiveness, ensuring the integrity of every soldered connection. Furthermore, our ovens incorporate larger aluminum alloy heat plates, effectively reducing power consumption and carbon emissions, aligning with our commitment to sustainability in manufacturing. Experience the future of reflow soldering tailored to the specific needs of mobile charger and adaptor production with MTI Connectech's KS-635 6 Zone SMT Reflow Ovens, where precision and sustainability converge to set new standards in manufacturing excellence.